Occupational Hygiene

Legislation

Employers in British Columbia, Alberta, Saskatchewan along with other provinces and territories across Canada are legally responsible for identifying, assessing, and managing hazardous materials within the workplace. Under provincial occupational health and safety legislation, this includes conducting hazard assessments, maintaining current inventories, ensuring the safe handling and removal of substances like asbestos, lead, and silica, and providing worker training and access to Safety Data Sheets (SDS). These regulations are designed to protect workers, occupants, and the public, and to ensure safe conditions during maintenance, renovations, or demolition activities.

-Alberta OHS requirements – Part 4 of the OHS Code specifically speaks to “Chemical Hazards, Biological Hazards and Harmful Substances”.

-Worksafe BC requirements – Part 5 of the OHS Regulation details “Chemical Agents and Biological Agents” and Part 6 provides details pertaining to “Substance Specific Requirements”.

-Worksafe Sask requirements – Part III (General Duties) and Part X (Chemical and Biological Substances) are key sections related to hazardous substances.

Occupational Exposure Limits (OELs)

Occupational Exposure Limits (OELs) are regulatory limits on the amount or concentration of a hazardous substance in workplace air. They are established to protect workers’ health by defining safe levels of exposure during a typical workday (usually an 8-hour time-weighted average) or over a short term.

Key types of OELs:

- TWA (Time-Weighted Average): Average exposure over an 8-hour shift.

- STEL (Short-Term Exposure Limit): Maximum exposure allowed over a 15-minute period.

- Ceiling Limit (C): The concentration that must not be exceeded at any time.

OELs are used to evaluate workplace monitoring results and determine whether control measures—such as ventilation, process changes, or PPE—are necessary to reduce or eliminate exposure to hazardous substances.

Respiratory codes of practice

A Respiratory Code of Practice is a required document that outlines how an organization manages the proper selection, use, and maintenance of respiratory protective equipment (RPE). It includes hazard assessments, respirator selection, fit testing, worker training, medical evaluations, and maintenance procedures. This ensures workers are protected from airborne hazards and that the employer complies with occupational health and safety regulations.

Exposure Assessments

Before any task is carried out, careful consideration must be given to the hierarchy of controls. This process is essential for identifying the most effective methods to eliminate or minimize exposure to hazards. Starting with elimination and substitution, and progressing through engineering controls, administrative controls, and finally personal protective equipment (PPE), each level should be evaluated to ensure that the most effective and practical risk reduction measures are implemented. This proactive approach not only protects workers but also supports compliance with regulatory standards and promotes a strong safety culture on site. Our team can aid in identifying and implementing the hierarchy of controls.

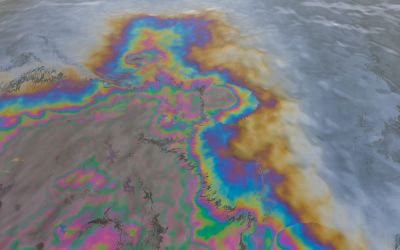

BTEX

BTEX or Benzene, Toluene, Ethylbenzene, and Xylenes are volatile organic compounds commonly found in petroleum products. They are environmental contaminants often linked to fuel spills or leaks and can pose serious health risks, including cancer (benzene).

Volatile Organic Compounds (VOCs)

Volatile Organic Compounds (VOCs) are chemicals that can evaporate into the air and are commonly found in workplaces that use solvents, fuels, coatings, or cleaning agents. Workplace assessments often include VOC monitoring to ensure air quality meets regulatory standards, do not exceed OELs, and to help implement appropriate control measures.

ACIDS

Acids in the workplace are commonly used in industrial processes such as cleaning, etching, and chemical manufacturing. Examples include sulfuric acid, hydrochloric acid, and nitric acid. These substances can be highly corrosive and pose serious health and safety risks, including chemical burns, respiratory irritation, and eye damage.

Workplace assessments involving acids typically evaluate storage, handling procedures, ventilation, spill response, and the use of appropriate personal protective equipment (PPE) to ensure worker safety and regulatory compliance.

Naturally Occurring Radioactive Materials (NORMs)

Naturally Occurring Radioactive Materials (NORMs) are radioactive isotopes such as uranium, thorium, potassium, and decaying isotopes like Radon that are naturally present in the earth. In workplace settings—particularly in oil and gas, mining, and water treatment—NORMs can accumulate on equipment or be released during processing activities. Workplace assessments may include radiation surveys and sampling to evaluate exposure levels and ensure compliance with regulations.

Hydrogen Sulfide (H2S)

Hydrogen Sulfide (H₂S) is a toxic, colorless gas with a characteristic rotten egg smell, commonly found in industries such as oil and gas, wastewater treatment, and agriculture. Workplace monitoring includes continuous gas detection and personal monitoring to ensure levels stay within safe limits. Proper ventilation, emergency response plans, and personal protective equipment are essential to protect workers from H₂S hazards.

Exposure Control Plans

Exposure Control Plans (ECPs) are formal documents developed to identify workplace hazards and outline the procedures and controls needed to minimize employee exposure to harmful substances or conditions. These plans typically include hazard assessment, engineering and administrative controls, use of personal protective equipment (PPE), employee training, and monitoring protocols. ECPs are essential for compliance with occupational health and safety regulations and help ensure a safe working environment.

Worker Exposure

Once a hazard has been identified or there is a concern about potential worker exposure, exposure assessment through air or surface sampling may be necessary. Sampling helps to quantify the level of risk, determine the effectiveness of existing control measures, and ensure compliance with applicable occupational health and safety regulations. By collecting accurate data, employers can make informed decisions about the need for additional controls, adjustments to work practices, or medical surveillance. This process is a critical component of a comprehensive hazard management strategy and supports the overall goal of maintaining a safe and healthy work environment.

Welding Fume

Welding fumes are a complex mixture of metallic oxides, gases, and particulates generated during welding processes. These fumes can contain harmful substances such as manganese, chromium, and nickel, which pose respiratory and systemic health risks to workers. Workplace assessments for welding fumes involve air monitoring to evaluate exposure levels, ensuring compliance with occupational exposure limits, and implementing engineering controls, ventilation, and personal protective equipment to minimize health hazards.

Respirable Particulate

Respirable particulates are fine airborne particles with a diameter small enough to reach the gas-exchange regions of the lungs. Commonly generated by activities such as grinding, welding, and combustion processes, these particulates pose significant respiratory health risks. Occupational assessments focus on measuring respirable particulate levels to evaluate worker exposure, ensure compliance with regulatory standards, and implement effective control measures to protect worker health.

Asbestos Exposure Monitoring

Asbestos occupational monitoring involves measuring airborne asbestos fiber levels in the workplace to assess worker exposure during activities such as removal, maintenance, or demolition. This monitoring typically includes air sampling followed by analysis using methods like Phase Contrast Microscopy (PCM) or Transmission Electron Microscopy (TEM). The goal is to ensure exposures remain below regulatory limits, verify the effectiveness of control measures, and protect worker health by preventing asbestos-related diseases.

Silica Exposure Monitoring

Silica exposure monitoring involves measuring airborne respirable crystalline silica levels in workplaces where activities like cutting, grinding, or drilling silica-containing materials occur. Air samples are collected and analyzed to assess worker exposure and ensure compliance with occupational exposure limits. Monitoring helps identify the need for engineering controls, work practices, and personal protective equipment.

Noise Dosimetry

Noise dosimetry measures a worker’s noise exposure over a shift using a personal dosimeter. This process aids in the identification of overexposure, supports hearing protection programs, and ensures compliance with occupational noise limits.

Isocyanates

Isocyanates are highly reactive chemicals used in the production of foams, coatings, paints, adhesives, and insulation materials. Common types include MDI (methylene diphenyl diisocyanate) and TDI (toluene diisocyanate). Worker exposure assessments for isocyanates often include air monitoring, reviewing application methods (e.g., spraying), evaluating ventilation, and confirming the use of proper PPE.

Hazardous Materials Management

Whether you’re managing renovations, maintenance, or daily operations, our thorough Hazardous Materials Building Assessments and tailored Management Plans help you identify risks, ensure compliance, and maintain a safe environment for your employees and community. Partner with us for peace of mind and professional support every step of the way.

Hazardous materials building assessments

Hazardous Materials Building Assessments involve a thorough inspection and evaluation of a facility to identify the presence, condition, and potential risks of hazardous materials such as asbestos, lead, mold, chemicals, and other contaminants. These assessments help determine necessary remediation or management strategies to ensure occupant safety, regulatory compliance, and proper handling during renovations, demolitions, or routine maintenance. They typically include sampling, risk evaluation, and detailed reporting.

Hazardous Materials management plans

Hazardous Materials Management Plans are comprehensive strategies developed to safely handle, store, transport, and dispose of hazardous substances within a facility or workplace. These plans outline procedures for hazard identification, risk assessment, control measures, emergency response, employee training, and regulatory compliance. Effective management plans help minimize health and environmental risks, prevent accidents, and ensure safe operations involving hazardous materials.

FREE CONSULTATION

OVER 20 YEARS OF EXPERIENCE

By being meticulous with our Occupational Hygiene processes, you can rest assured that we get the job done right the first time. Call now for more information or to schedule your on-site assessment.